What is the Meaning of Stock Availability?

Stock availability or product availability refers to the ability of a business to provide products to customers as and when they are demanded. It is a fundamental aspect of inventory management that directly impacts customer satisfaction, brand reputation, and overall sales performance.

If a business fails to meet these expectations due to stockouts, it risks losing customers to competitors. Conversely, maintaining excessive stock can lead to unnecessary holding costs and potential wastage. Hence, striking a balance in stock levels is crucial for maximizing sales and ensuring operational efficiency.

Image Source: 42Signals – Stock Availaiblity Analytics

How Stock Availability Analytics Can Drive Your E-Commerce Business Forward

Stock availability analytics leverages data-driven insights to optimize inventory levels, predict demand fluctuations and prevent stockouts or overstocking. By utilizing advanced analytics, businesses can improve supply chain visibility, forecast trends more accurately, and ensure that their products remain available without excessive surplus.

With tools such as AI-driven predictive analytics, businesses can monitor stock levels in real time and automate replenishment processes. This proactive approach ensures better inventory control and enhances the customer shopping experience, thereby fostering loyalty and repeat business.

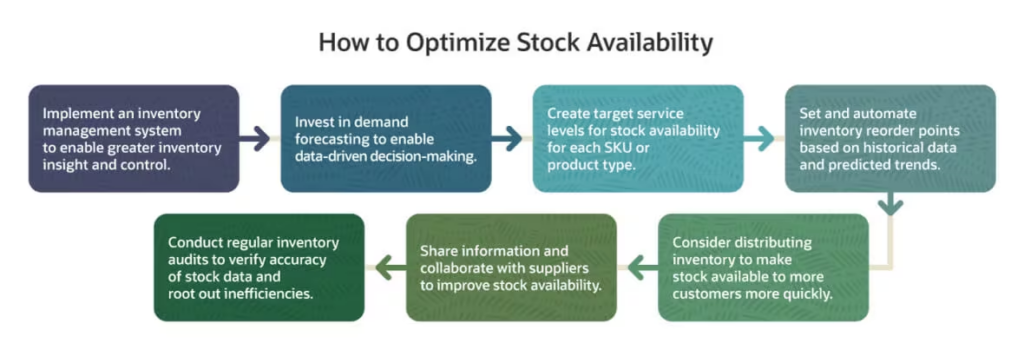

Image Source: NetSuite

Assessing Current Stock Availability Practices

Evaluating Your Inventory Health

Regular assessments of inventory health are essential to ensure optimal stock availability. This involves analyzing key metrics such as:

- Stock Turnover Rate: Measures how frequently inventory is sold and replaced.

- Aging Stock Analysis: Identifies slow-moving products that might need promotional strategies to clear.

- Inventory Accuracy Rate: Ensures data records align with actual stock levels.

By continuously evaluating these factors, businesses can identify inefficiencies and take corrective actions to optimize stock availability.

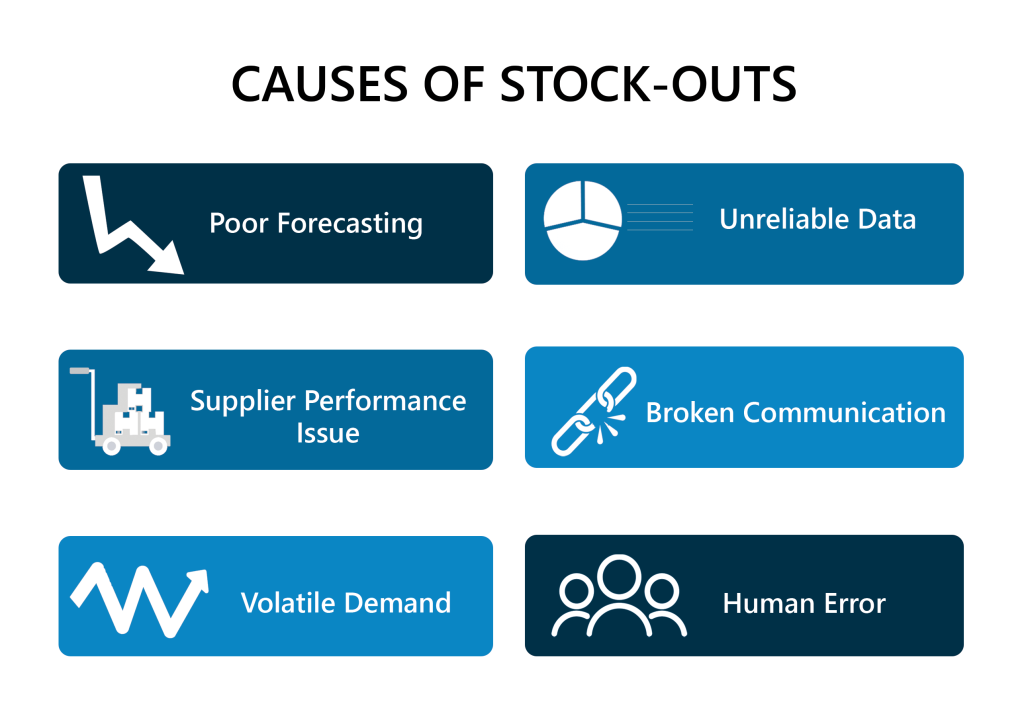

Identifying Gaps in Your Stock Availability Management

Analyzing stock management practices helps pinpoint weaknesses in inventory control. Common gaps include:

- Inefficient Reordering Processes: Delays in reordering can lead to stockouts.

- Poor Demand Forecasting: Inaccurate projections result in excess or insufficient stock.

- Unreliable Suppliers: Supplier inconsistencies disrupt stock flow.

By addressing these gaps, businesses can enhance their inventory strategy and prevent potential sales losses due to stock unavailability.

Best Practices for Managing Stock Availability

Implementing Robust Inventory Replenishment Systems

A well-structured replenishment system ensures stock levels are consistently maintained. Key strategies include:

- Automated Reordering: Setting up automatic restocking triggers based on demand patterns.

- Just-In-Time (JIT) Inventory: Reducing holding costs by replenishing stock only when needed.

- Multi-Supplier Approach: Having backup suppliers to mitigate disruptions.

Developing an Efficient Reordering Process

An effective reordering process ensures seamless stock replenishment. Best practices include:

- Setting Reorder Points: Establishing minimum stock thresholds to trigger replenishment.

- Utilizing Vendor-Managed Inventory (VMI): Allowing suppliers to monitor and manage inventory levels.

- Batch Ordering: Consolidating orders to optimize shipping costs and efficiency.

Just-In-Time Inventory Versus Safety Stock Strategies

Businesses must balance JIT inventory with safety stock strategies to mitigate risks:

- JIT Inventory: Minimizes storage costs but may cause stockouts if demand spikes unexpectedly.

- Safety Stock: Maintains a buffer stock to handle demand fluctuations, reducing the risk of lost sales.

An optimal approach often involves a hybrid strategy, where critical products have safety stock, while less crucial items follow JIT principles.

Stock Availability: Roadblocks & Ways to Improve

Building Strong Relationships with Suppliers

Supplier reliability plays a key role in stock availability. Strengthening relationships with suppliers can be achieved by:

Collaborating on Demand Planning: Sharing sales data with suppliers to improve forecasting accuracy.

Negotiating Favorable Terms: Ensuring flexibility in lead times and payment terms.

Implementing Supplier Scorecards: Evaluating supplier performance based on delivery times, quality, and reliability.

Navigating Supply Chain Disruptions

Supply chain disruptions, such as geopolitical issues, natural disasters, or pandemics, can severely impact stock availability. Businesses can mitigate these risks through:

Implementing Agile Supply Chain Practices: Enhancing flexibility to quickly adapt to changes.

Diversifying Suppliers: Sourcing from multiple suppliers to avoid over-dependence on one.

Maintaining Emergency Stock: Keeping a buffer of essential items to handle disruptions.

Aligning Inventory with Market Demand

Accurate demand forecasting is essential for aligning stock levels with market trends. Businesses can improve forecasting by:

Monitoring Consumer Behavior: Tracking customer preferences to adjust inventory accordingly.

Analyzing Sales Trends: Studying past sales data to predict future demand.

Leveraging AI & Machine Learning: Using technology to detect patterns and optimize stock levels.

Learning from Stockouts and Surpluses

Analyzing Stockout Incidents

Stockouts indicate a failure in inventory planning. Businesses should analyze stockout instances to:

- Enhance Inventory Policies: Implement buffer stocks for high-demand products.

- Identify Causes: Assess whether stockouts result from supplier delays, poor forecasting, or unexpected demand surges.

- Improve Forecasting Models: Adjust demand projections based on past mistakes.

Image Source: Slimstock

Managing Overstock Situations

Excess inventory ties up capital and storage space. Strategies to reduce overstock include:

- Running Promotions & Discounts: Moving excess stock through special offers.

- Expanding Distribution Channels: Selling surplus through online marketplaces or bulk buyers.

- Adjusting Ordering Cycles: Refining procurement plans to prevent overstocking.

Agile Adaptation to Changing Consumer Patterns

Consumer preferences and market trends are constantly evolving. Businesses must adopt an agile approach to stock management by:

Improving Omnichannel Integration: Ensuring seamless stock availability across online and offline channels.

Monitoring Industry Trends: Keeping track of emerging consumer demands.

Utilizing Real-Time Data Analytics: Making swift inventory adjustments based on sales insights.

Conclusion on Stock Availability

Effectively managing stock is a dynamic process that requires ongoing attention and strategic planning. Businesses must focus on optimizing demand forecasting, maintaining efficient inventory management, and building strong supplier relationships to ensure seamless product availability.

By implementing best practices, companies can minimize stockouts, reduce excess inventory, and enhance customer satisfaction. Leveraging advanced stock availability analytics further helps in making data-driven decisions that maximize sales and operational efficiency.

42Signals helps businesses optimize their stock availability and provides granular insights into how to optimize product management.

For a free demo, contact us at sales@42signals.com

Frequently Asked Questions

What is the meaning of stock availability?

Stock availability refers to the quantity of a product that is currently in inventory and ready for purchase. It ensures that customers can buy products without delays or backorders.

How do you say stock is available?

Common phrases used to indicate stock availability include:

- “In stock”

- “Available for immediate shipping”

- “Limited stock – order soon!”

- “Back in stock soon” (if temporarily unavailable but expected soon)

What is the definition of available stock?

Available stock refers to the quantity of a product that is physically present in inventory and ready for sale, excluding reserved or damaged items.

What factors affect stock availability?

- Supplier delays – Late shipments from manufacturers

- Demand fluctuations – Seasonal spikes in demand

- Inventory mismanagement – Poor tracking of stock levels

- Supply chain disruptions – Shipping delays, production issues

What is a good stock availability percentage?

An ideal stock availability rate is 95% or higher, ensuring most customer orders can be fulfilled without backorders.

How can businesses improve stock availability?

- Use inventory management software to track stock levels in real-time

- Work with reliable suppliers for consistent replenishment

- Forecast demand accurately using sales data and trends

- Implement automated restocking to prevent stockouts

What is the difference between stock availability and stock quantity?

- Stock availability refers to whether an item is currently ready for sale.

- Stock quantity is the total number of units available, including reserved or incoming stock.

How do e-commerce platforms display stock availability?

E-commerce websites often display stock availability using:

- Green checkmarks for “In stock” items

- Red warnings for “Out of stock” or “Limited stock” items

- Backorder notifications for items available for future purchase