The ability to manage product availability effectively to meet consumer demand is a cornerstone of successful business operations. Companies that master this aspect not only satisfy their customers but also gain a competitive edge, ensuring profitability and sustainability.

Let’s look at the various strategies and challenges associated with managing product availability, highlighting key practices and technological advancements that aid in achieving this critical balance.

1. Understanding Consumer Demand

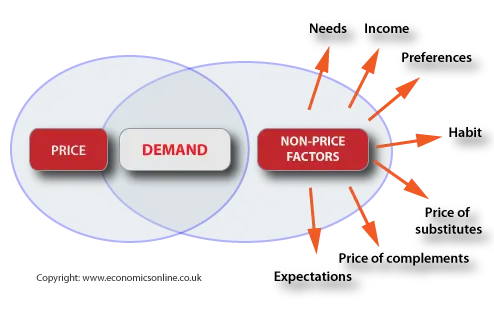

Consumer demand is the driving force behind any successful business. It represents the desire and willingness of consumers to purchase goods and services at various price levels. Understanding this demand involves analyzing patterns, trends, and preferences. Companies use various tools and methodologies to forecast demand, including historical sales data, market research, and predictive analytics.

Image Source: Economics Online

Demand Forecasting

Accurate demand forecasting is essential for managing product availability. Companies employ statistical methods and machine learning algorithms to predict future demand based on historical data. These forecasts help in making informed decisions about inventory levels, production schedules, and supply chain management.

2. Inventory Management

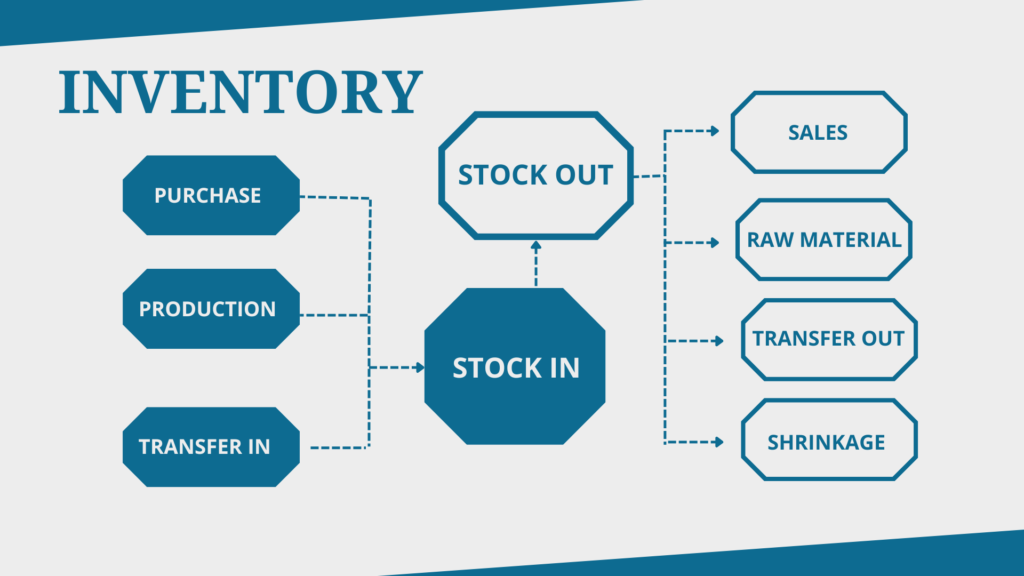

Inventory management is the process of overseeing and controlling the ordering, storage, and use of products. It aims to ensure that the right quantity of products is available at the right time. Effective inventory management minimizes costs and maximizes customer satisfaction.

Image Source: Cash Flow Inventory

Just-In-Time (JIT) Inventory

The Just-In-Time inventory system is a strategy where materials and products are ordered and received only as they are needed in the production process. This method reduces the cost of holding inventory and minimizes waste. However, it requires precise demand forecasting and a highly responsive supply chain to avoid stockouts and delays.

Safety Stock

Safety stock acts as a buffer against uncertainties in demand and supply. By maintaining extra inventory, businesses can protect themselves from unexpected spikes in demand or disruptions in the supply chain. Calculating the right amount of safety stock is crucial; too much can tie up capital, while too little can lead to stockouts and lost sales.

3. Supply Chain Management in Product Availability

A well-managed supply chain ensures that products are delivered efficiently and cost-effectively from suppliers to customers. It involves coordinating all the activities related to sourcing, procurement, production, and logistics.

Image Source: Britannica

Supplier Relationships

Building strong relationships with suppliers is vital for ensuring a reliable supply of products. Collaborative partnerships can lead to better communication, faster response times, and more favorable terms. Companies often work closely with suppliers to improve quality, reduce lead times, and implement just-in-time deliveries.

Logistics and Distribution

Efficient logistics and distribution systems are critical for getting products to the right place at the right time. Companies invest in advanced transportation management systems (TMS) and warehouse management systems (WMS) to optimize routes, manage inventory in transit, and ensure timely deliveries.

4. Technology and Automation

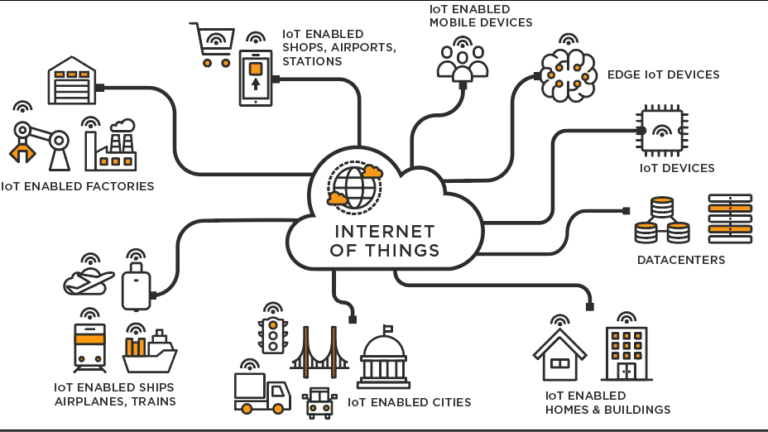

The advent of technology and automation has revolutionized the way businesses manage product availability. From sophisticated forecasting tools to automated inventory management systems, technology plays a pivotal role in enhancing efficiency and accuracy.

Image Source: Business Tech

Artificial Intelligence & Machine Learning

AI and machine learning algorithms can analyze vast amounts of data to identify patterns and trends that human analysts might miss. These technologies improve demand forecasting accuracy and enable real-time adjustments to inventory levels based on changing conditions.

Internet of Things (IoT)

IoT devices, such as smart sensors and RFID tags, provide real-time data on inventory levels, product conditions, and movement throughout the supply chain. This information helps businesses monitor stock levels, reduce shrinkage, and improve overall supply chain visibility.

Blockchain Technology

Blockchain offers a transparent and secure way to track products throughout the supply chain. It ensures the authenticity and traceability of goods, reducing the risk of fraud and improving trust between parties.

5. Challenges in Managing Product Availability

Despite the advancements in technology and strategies, managing product availability comes with a set of challenges. These include demand variability, supply chain disruptions, and the complexities of global markets.

Image Source: 42Signals – Product Availability Analytics

Demand Variability

Consumer demand is inherently unpredictable and can be influenced by various factors such as seasonality, economic conditions, and changing preferences. Businesses must be agile and responsive to adapt to these fluctuations.

Supply Chain Disruptions

Natural disasters, political instability, and transportation issues can disrupt the supply chain, leading to delays and stockouts. Companies need contingency plans and risk management strategies to mitigate these disruptions.

Global Market Complexities

Operating in a global market adds layers of complexity due to different regulations, cultural differences, and logistical challenges. Businesses must navigate these complexities while maintaining efficient and consistent inventory levels.

6. Strategies for Improvement

To overcome these challenges and improve inventory levels, businesses can adopt several strategies:

Collaborative Planning, Forecasting & Replenishment (CPFR)

CPFR involves collaboration between supply chain partners to share forecasts, production plans, and inventory data. This collaborative approach leads to more accurate forecasts, reduced inventory levels, and improved product availability.

Lean Inventory Management

Lean principles focus on minimizing waste and maximizing efficiency. By adopting lean inventory management practices, businesses can reduce excess inventory, streamline processes, and improve response times.

Advanced Analytics

Leveraging advanced analytics helps businesses gain deeper insights into consumer behavior and market trends. These insights enable more accurate demand forecasting and better decision-making regarding inventory and supply chain management.

Customer Relationship Management (CRM)

A robust CRM system helps businesses understand customer preferences, track sales trends, and anticipate future demand. By aligning inventory and production with customer needs, companies can ensure higher item availability and customer satisfaction.

Conclusion

Managing product availability to meet consumer demand is a multifaceted challenge that requires a combination of accurate demand forecasting, efficient inventory management, and robust supply chain practices. The integration of advanced technologies such as AI, IoT, and blockchain further enhances the ability to maintain optimal inventory levels.

The key lies in balancing the intricate dance between supply and demand, leveraging technology, and fostering strong relationships across the supply chain.

42Signals helps brands understand, forecast, and manage inventory levels optimally to ensure no disruption in the supply chain.

What’s better is that our platform can deal with unique requirements and help you with the exact data you need to improve sales. Interested? Schedule a demo to get started.