Efficient inventory management lies at the heart of any thriving e-commerce venture, ensuring seamless operations, satisfied customers, and healthy profit margins. Striking the ideal equilibrium between having enough stock to satisfy demand without tying up excessive capital in slow-moving items can be challenging. To help navigate this complex landscape, we’ve compiled eight essential strategies for optimizing inventory levels and illustrative examples showcasing each strategy in action.

Steps to Optimize Inventory Levels

1. Understand Your Lead Time

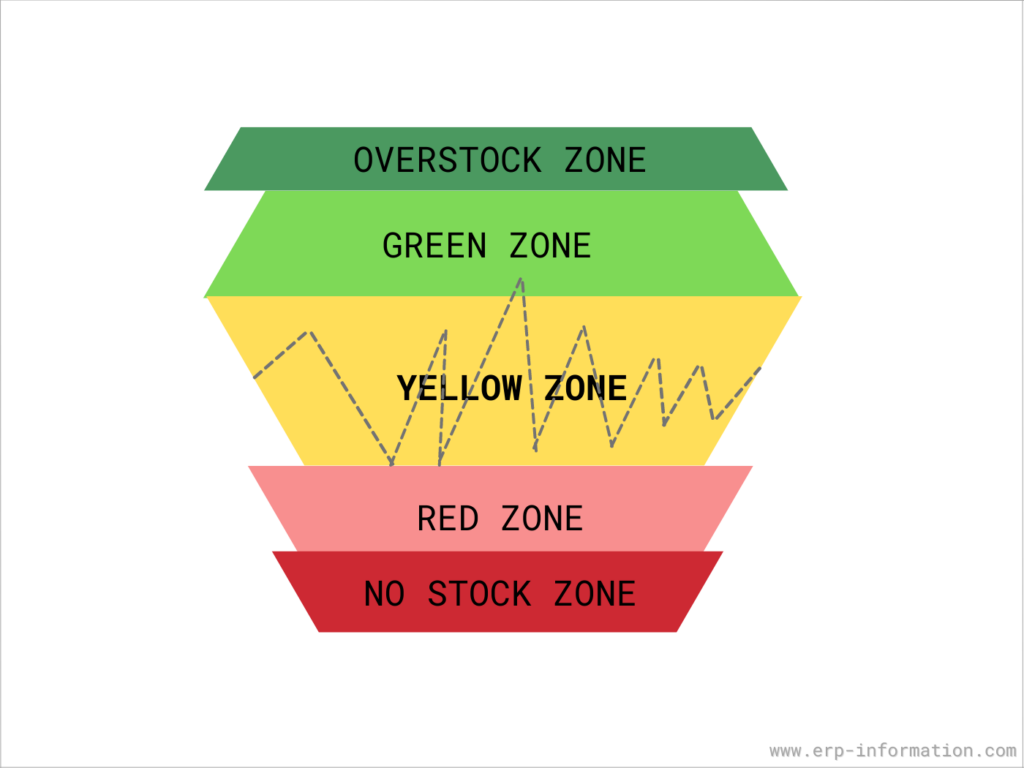

Lead time refers to the duration between placing an order with your supplier and receiving it in your warehouse. Accurately estimating lead times allows you to plan better and maintain optimal inventory levels.

It’s crucial to consider factors such as production schedules, shipping methods, customs clearance (if applicable), and holidays when calculating lead times. Regularly reviewing these variables will enable you to make informed decisions about reordering points and quantities.

Image Source: ERP Information

2. Analyze Sales Data to Understand Inventory Levels

Historical sales data provides valuable insights into consumer behavior patterns and seasonal trends. By analyzing past sales figures, you can identify which products sell fastest during specific periods, enabling you to adjust inventory levels accordingly. Additionally, forecasting tools can predict future demand based on historical data, helping you avoid stockouts or overstock situations.

For instance, if winter coats fly off the shelves every year from September through November, boosting inventory levels during summer months ensures adequate supply once peak season arrives. Moreover, advanced forecasting tools harness machine learning algorithms to predict upcoming demand fluctuations accurately, empowering businesses to stay one step ahead.

Example: Fashion retailer Zara uses big data analytics and AI-driven forecasting models to analyze sales trends across various regions, styles, and sizes, tailoring its inventory mix accordingly. This approach has contributed significantly to Zara’s rapid global expansion and industry-leading profitability.

3. Implement a Safety Stock Strategy

Safety stock acts as a buffer against unexpected spikes in demand or supply chain disruptions. Calculating the appropriate safety stock level involves determining the desired service level – i.e., the probability of not experiencing a stockout – and accounting for variability in both lead times and demand.

Image Source: Myos

Mishaps happen—suppliers encounter delays, natural disasters disrupt manufacturing plants or sudden surges in demand outstrip available stocks. Safeguarding yourself against these uncertainties necessitates holding extra inventory and keeping high inventory levels. The key lies in striking the right balance between protection against unforeseen events and unnecessary storage expenses.

Example: Amazon maintains substantial safety stock reserves for popular products sold via its platform, guaranteeing timely delivery even amidst logistical snags or unprecedented demand spikes.

4. Utilize ABC Analysis

ABC analysis categorizes items based on their importance regarding revenue contribution and inventory costs. Generally, A-items account for a large portion of revenues but represent only a small percentage of total SKUs; B-items contribute moderately to revenues and inventory costs, while C-items have minimal impact on either metric.

Classifying inventory items according to their respective contributions to overall revenue and inventory cost enables focused attention to where it matters most. Prioritize top-performing A-items by tightly controlling their inventories, while allocating fewer resources to low-impact C-items.

Example: Home Depot employs ABC analysis to segment its vast array of products, dedicating prime shelf space and aggressive marketing campaigns to high-margin A-items, thus fueling impressive sales growth year after year.

5. Adopt Just-in-Time (JIT) Inventory Management

Just-in-time (JIT) inventory management focuses on procuring goods only when they are needed, thereby reducing carrying costs and improving cash flow. However, implementing JIT successfully demands exceptional precision in forecasting demand, coordinating with suppliers, and synchronizing internal processes. As such, it might not be suitable for all businesses or product categories, particularly those susceptible to market volatility or extended lead times.

Minimize carrying costs and optimize cash flow by adopting just-in-time (JIT) inventory management principles. Procuring goods only when required entails close coordination with suppliers and meticulous demand forecasting. Although riskier than traditional approaches, JIT offers significant benefits for nimble e-commerce businesses capable of executing it flawlessly.

Example: Toyota famously implemented JIT throughout its manufacturing processes, slashing waste, reducing lead times, and bolstering competitiveness—all without compromising quality standards.

6. Monitor Supplier Performance for Optimal Inventory Levels

Establishing strong relationships with reliable suppliers is vital for effective inventory management. Consistently delivering quality products within agreed deadlines enables you to maintain accurate inventory records, minimize lead times, and respond swiftly to changing market conditions. Periodically evaluating supplier performance also helps identify potential areas for improvement and fosters continuous process optimization.

Example: Ikea collaborates closely with longstanding vendors to secure favorable pricing terms, guaranteed availability, and customized packaging options, reinforcing its position as the go-to destination for affordable home furnishings.

7. Automate Inventory Management Processes

Automation reduces manual intervention, increases efficiency, and mitigates errors associated with managing inventories manually. Integrated systems like enterprise resource planning (ERP) software or specialized inventory levels management solutions facilitate real-time tracking of stock availability, auto-generation of purchase orders, and automatic updates across multiple channels. Furthermore, automation frees up time and resources, allowing you to focus on strategic decision-making and growth initiatives.

Image Source: BlueCart

Example: Walmart deploys cutting-edge robotics and AI-powered autonomous vehicles to expedite picking, packing, and sorting activities within its distribution centers, augmenting employee productivity and elevating customer experiences.

8. Establish Effective Communication Channels

Open communication lines between departments involved in procurement, warehousing, and fulfillment ensure smooth information exchange concerning inventory status, lead times, and other relevant metrics. Sharing best practices, lessons learned, and success stories promotes cross-functional collaboration and drives collective progress toward achieving optimal inventory levels.

Example: Costco owes much of its success to its employees’ dedication to teamwork and camaraderie. Cross-departmental collaboration facilitates swift resolution of challenges, prompt adaptation to shifting circumstances, and sustained enhancement of inventory management practices.

Conclusion on Inventory Levels

Achieving optimal inventory levels demands careful consideration of numerous interconnected factors, ranging from historical sales data and forecasting methodologies to supplier relations and technology investments.

With several systems and software out there, managing inventories is easier than ever. 42Signals helps businesses with such requirements by allowing them to understand inventory levels at multiple locations and stocking them accordingly.

This data proves beneficial in the long run and helps improve operations across multiple stores. To know more, schedule a demo with us today.

Frequently Asked Questions

What are the 4 inventory stock levels?

The four main inventory stock levels that businesses track are:

- Minimum Stock Level – The lowest amount of stock a business should maintain to avoid stockouts.

- Reorder Level – The stock level at which new inventory should be ordered to prevent shortages.

- Maximum Stock Level – The highest quantity of stock a company should hold to prevent overstocking.

- Danger Level – The critical low stock level that may disrupt operations if not replenished immediately.

How to determine inventory levels?

To determine optimal inventory levels, businesses follow these steps:

- Analyze Demand Trends – Use sales history and demand forecasting.

- Calculate Reorder Points – Use the formula: Reorder Point=(Average Daily Usage×Lead Time)+Safety Stock\text{Reorder Point} = (\text{Average Daily Usage} \times \text{Lead Time}) + \text{Safety Stock}Reorder Point=(Average Daily Usage×Lead Time)+Safety Stock

- Monitor Inventory Turnover Ratio – Helps in determining how frequently stock is replenished.

- Use Inventory Management Software – Tools like Zoho Inventory, NetSuite, and TradeGecko automate tracking.

What are the 4 types of inventory?

The four primary types of inventory in supply chain management are:

- Raw Materials Inventory – Unprocessed materials used in manufacturing (e.g., wood, metals).

- Work-in-Progress (WIP) Inventory – Items in production but not yet completed.

- Finished Goods Inventory – Products ready for sale to customers.

- MRO Inventory (Maintenance, Repair, and Operations) – Supplies used to maintain operations but not sold as finished goods (e.g., tools, cleaning supplies).

What are the different levels of inventory?

Inventory is categorized into multiple levels depending on supply chain needs:

- Cycle Stock – Regular inventory maintained for normal demand cycles.

- Safety Stock – Extra stock kept to cover unexpected demand surges.

- Pipeline Inventory – Goods in transit from suppliers to warehouses or retailers.

- Seasonal Inventory – Stock maintained to meet seasonal demand fluctuations.

- Dead Stock – Unsold inventory that is outdated or obsolete.

How can businesses optimize inventory levels?

- Implement Just-in-Time (JIT) inventory management to reduce waste.

- Use ABC analysis to prioritize inventory items based on value and turnover.

- Track real-time inventory data with AI-driven demand forecasting tools.